The inventory of an e-commerce business is typically its most valuable asset. Once your WIP inventory is converted into sellable items, you will need a system in place to monitor inventory as it is sold. The ability of manufacturers to satisfy demand and deliver orders on time will improve, which will lead to a rise in customer satisfaction. Enhancing client satisfaction requires, among other things, making sure that orders are completed on time. Just-in-time production and cellular manufacturing are related concepts. With the help of this tactic, a company may give clients the goods they want, when they want them, in the amounts they want.

Work in Process Inventory – What Is WIP and How To Calculate it?

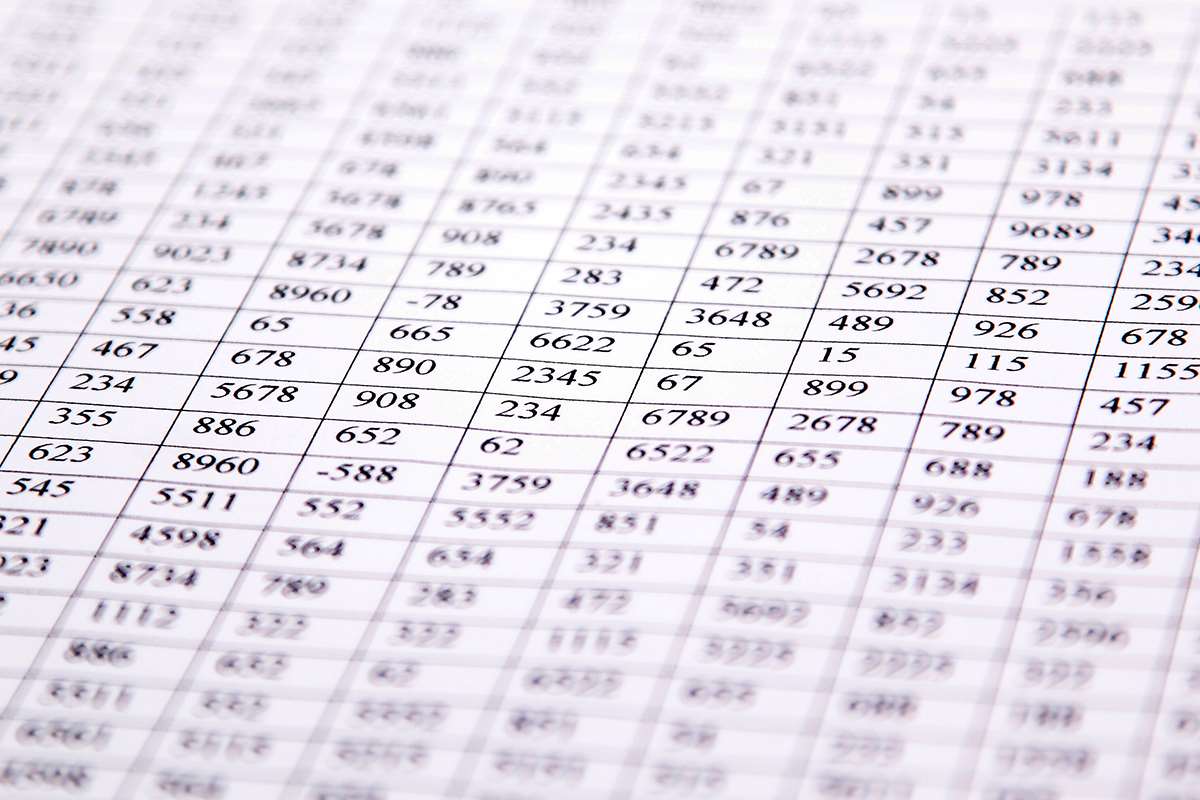

- ABC has five workers on its assembly line and they are each paid an annual salary of $40,000.

- Implementing manufacturing accounting systems, especially those designed for discrete manufacturing, is like automating the ship’s course, allowing for a more efficient journey.

- With the help of manufacturing software, it’s easier to manage inventory, figure out the average cost of making each item according to accounting standards, and ensure there’s enough on the shelf without overflowing.

- Conversely, you record an increase to a revenue account as a credit and an increase to an expense account as a debit.

- However, at the same time, they are not fully processed and cannot be called finished goods.

- Get a demo of Katana, and see why thousands of manufacturers trust Katana to manage their entire business.

Work in process (WIP) inventory is an important line item on a merchant’s balance sheet and a key indicator of the health of their supply chain. WIP inventory is not applicable to merchants who purchase finished goods from a supplier for resale. However, if your procurement process looks anything like the following three scenarios, you should be tracking and calculating your WIP inventory. QuickBooks Enterprise is a complete solution for inventory management, manufacturing accounting offering everything from one-click processing and mobile scanning to inventory analysis and reporting. It has everything you need to keep your products, customers, and transactions synced and secure, freeing you up to focus on your business. If you want to refine your production process and automate aspects of your business, accurate costing information helps you identify wasteful costs passed on to the customer or absorbed within the company.

Enhanced Inventory Management and Planning:

- The term “work in progress” (WIP) is used to describe how manufacturing costs move from one stage of production to another.

- Finished goods refer to the final stage of inventory, in which the product has reached a level of completion where the subsequent stage is the sale to a customer.

- Some businesses may manufacture their own products instead of trading in finished goods.

- Overhead costs include expenses like factory rent, utilities, and administrative costs.

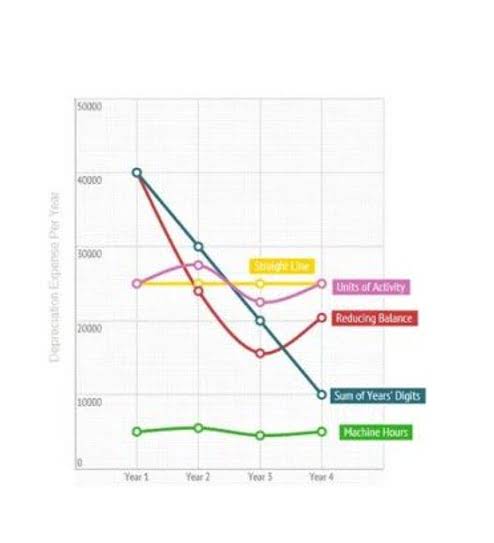

While larger companies can absorb a few more errors due to scale and averaging, small and medium-sized companies often have little to no room for error. Here are five reasons why accurate WIP accounting is a must, regardless of company size. The beginning work in progress inventory is the ending balance from the prior https://www.bookstime.com/ accounting period, i.e. the closing carrying balance is carried forward as the beginning balance for the next period. A manufacturing business operates with complexities in the world of making things, from toys to tools. The manufacturing process needs careful accounting to keep everything running smoothly.

A guide to basic accounting for manufacturing businesses

To clarify where WIP inventory falls in the production process, let’s look at it in the larger context of other inventory classifications. All of the following terms are under the umbrellas of manufacturing inventory. In this article, we’ll cover the importance of classifying WIP inventory, how to calculate it, and how you can use the insights to optimize your inventory management.

WIP Inventory FAQ’s

Once the product has moved past WIP, it is classified as a finished goods inventory. WIP inventory figures are useful information to measure metrics related to the production process. Total manufacturing cost is an invaluable KPI for measuring the profitability of a business and can offer a quick insight into whether to set a higher selling price.

- WIP inventory includes the cost of raw materials, labor, and overhead costs needed to manufacture a finished product.

- Therefore, it is essential to collect updated visible WIP level data on a frequent basis utilizing a system that is simple and adaptable to requirements.

- They aren’t yet ready for sale and are still listed under the inventory asset account in a company’s balance sheet.

- Subledgers are “subdivisions” of account details for categories that you do not want in the permanent chart of accounts.

- This inventory stays on a company’s balance sheet or is written off based on the duration of time it spends on the production floor.

- Workers are better able to organize the steps that come before and after them, which speeds up task completion.